Using RDF as Alternative Fuel

- Introducing RDF as Alternative fuel

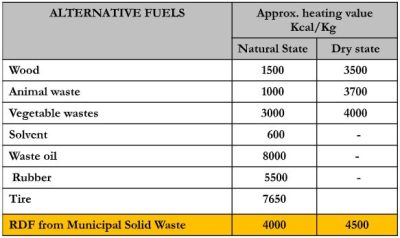

One viable and robust form of waste-to-energy from municipal solid waste is refuse derived fuel (RDF). Generally, RDF refers to the segregated high calorific fractions of waste from MSW: household, commercial, or industrial process wastes. RDF from municipal solid waste particularly is sorted portions, which consist of combustible components such as waste plastics, paper, cardboard, textiles, and wood with suitable Heat values ,as it’s shown in following photo and table:

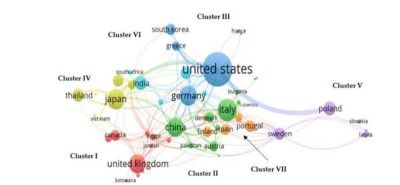

A total of 64 countries had engaged in collaborative works from the country co-authorship mapping, as shown in Figure 1, forming seven clusters with 179 links. In Cluster I, the UK was central among 14 nodes and 17 links between countries or territories around the world in RDF-related research. Sweden, Italy, and China had the closest collaboration, while others included Canada, Spain, Botswana, and Morocco. Clusters II and IV were largely made up of Asian and European countries. China and Italy were the central nodes in Cluster II. A total of 11 links of collaboration were observed between Italy and countries such as Romania, Spain, Germany, Austria, Portugal, Belgium, Netherlands, Taiwan, Sweden, and the UK. Among these, Romania and Italy had the largest collaboration with a link strength of seven. China had a total of 19 links with other countries such as Germany, Japan, and Finland. The central node of Cluster IV (14 links) was Japan, a strong collaboration with Thailand and Indonesia. The US was central in Cluster III, with a total of 10 nodes and 23 links of collaboration. Strong links also existed between Poland (nine), Japan (five), and Greece (five). Others were between US and Germany, Thailand, and China. Germany had collaborations existing between Austria, China, Brazil, the Czech Republic, Jordan, and Algeria. India was central in Cluster VI and had 10 links of collaboration, while Sweden in Cluster V exhibited 14 links of collaboration.

Bibliometric and network analysis of literature in refuse-derived fuel research from the Scopus database is presented. The data and analysis showed research within the refuse-derived fuel sphere stems back from the 1970s. Much of the development was found to be contributed from the US, China, Germany, and India. There are comparatively fewer contributions from the African region. Several locations within the sub-Saharan region are underdeveloped in terms of this theme, as issues on waste management and waste-to-energy become contextually driven. It was showed that the cooperation of countries was limited to specific territories: the US, Europe, and some Asian countries. This shows the need for improved efforts towards research collaboration within the field. This would improve the limited research contribution from especially developing countries and related issues of implementation. International collaborations also unveil opportunities for capacity building and technology transfer. The key journal sources of publications on refuse derived fuel included Waste Management, Fuel, Waste Management and Research, and the Journal of Cleaner Productions. Meanwhile, research was within the subject areas of environmental science, energy, and engineering. The thematic scope of the analyzed publications was diverse: conversion process, utilization, and management. Popularly, research in RDF application was in the cement process and electricity generation. Although a lot of research has been undertaken decades ago, there is still the need for advancement in processes, applications, and prospects. Few studies have been reported on thermochemical upgrading of RDF, material recovery (for example, hydrogen, as adsorbent, use of ash) other than energy from RDF and LCA (life cycle assessment) as the main research focus. Furthermore, circular economy and sustainability are in recent times highly rated and have become the direction for the most research.

- Canadian Cement producing companies

The Cement Association of Canada (CAC) comprises eight companies that operate 1 white and 15 Portland grey cement manufacturing facilities across Canada. The members of the association produce 98 percent of the cement manufactured in Canada.

Regionally, cement production is concentrated in central Canada. Ontario (50 percent) and Quebec (17 percent) have more than 65 percent of the industry’s capacity. The CAC is allied with the United States-based Portland Cement Association (PCA) and all CAC members are also members of the PCA.

The cement industry is a key contributor to Canada’s economic and social development. In 2006, the industry produced more than 14.3 million tones (t) of cement with a value of more than $1.7 billion and provided more than 2000 jobs. The industry’s total production is more than 16.7 million t when supplementary cementing materials such as fly ash and slag are included.

The cement manufacturing industry realized an 11 percent increase in energy efficiency per ton of cement produced between 1990 and 2006 and a corresponding reduction in greenhouse gas (GHG) intensity of 6.4 percent. However, the industry recognizes that further energy efficiency improvements are required to

- reduce energy costs and maintain industry competitiveness in a period of ever-increasing international competition

- make further progress in reducing the industry’s environmental footprint

- Municipal Waste Management in Canada

In Canada approximately 97% of the waste requiring final disposal is sent to landfills and 3% is incinerated. Provincial and territorial authorities establish waste reduction policies and programs and approve and monitor waste management facilities and operations including: incinerators, landfills and composting facilities. Municipalities are responsible the collection, recycling, composting and disposal of household waste.

Final waste treatment options such as landfilling and incineration have environmental impacts, including releases of pollutants to air and water. Today, by using advanced pollution control technologies and modern engineering, the health and environmental effects of waste disposal can be reduced.

Landfills

Landfilling is the primary method of municipal waste disposal in Canada. Modern municipal solid waste (MSW) landfills are designed and located to minimize the impacts on the social and natural environment as much as possible. Modern MSW landfills can collect and treat leachate – the rain water that accumulates and becomes contaminated as it travels through waste. When equipped with the proper technology, landfills can capture greenhouse gases which then can be used to produce energy or renewable natural gas.

It is important to know that even modern MSW landfills are not suitable for the disposal of hazardous waste. Such waste should only be disposed of in hazardous waste landfills. Hazardous waste landfills incorporate extra environmental protective measures, store wastes in a secure manner, while any potential emissions are minimized and carefully monitored.

Incineration

Modern incineration is a type of thermal treatment recognized as an effective method for eliminating a wide range of wastes. Different types of incinerators are used in Canada such as Waste-to-Energy (WTE) facilities, municipal wastewater sludge incinerators, hazardous waste incinerators and biomedical incinerators.

Incineration can reduce the volume of MSW by 90%. Today, incinerators use advanced air pollution controls and can include technologies that remove 99% of the dioxins and furans emitted from incineration. Additionally, best management practices are used in Canada such as implementation of the Canada-wide Standards for the emissions of dioxins/furans and mercury from waste incineration (CWS) developed by the Canadian Council of Ministers of the Environment (CCME):

For smaller incinerators, a Technical Document for Batch Waste Incineration provides guidance for owners and operators of batch waste incinerators to assist them in achieving the intent of the CWS, and reducing releases of other toxic substances.

Municipal solid waste organics processing

Composting biodegradable, food and yard waste is a very effective method of diverting a large proportion of municipal waste from landfill. Other benefits include a reduction of greenhouse gases and a reduction of leachate from landfills. The finished composting end product then can be used for many beneficial uses.

Northern and remote communities

Northern and remote communities face many unique challenges with waste management, such as limited or no access to: recycling programs, hazardous household waste disposal options and properly designed waste management facilities. This results in environmental and health risks for northern communities, especially when open waste burning is used as a disposal method.

Reducing and managing waste: contact information

Provinces and territories are responsible for the licensing and permitting of waste management operations including recycling centers, landfills and hazardous waste facilities. If you have questions regarding these operations, please contact your provincial or territorial Environment Ministry.

A list of provincial and territorial contacts is available for reference.

|

Province or territory |

Recycling council or association-direct contact |

| Alberta | Recycling Council of Alberta |

| British Columbia | Recycling Council of British Columbia |

| Manitoba | Sustainable Development Manitoba – Waste Wise |

| New Brunswick | Recycle New Brunswick |

| Newfoundland and Labrador | Multi Materials Stewardship Board |

| Northwest Territories | Department of Environment and Natural Resources |

| Nova Scotia | DivertNS |

| Nunavut | Department of Environment |

| Ontario | Stewardship Ontario |

| Prince Edward Island | Recycling Council of Ontario |

| Quebec | The Island Waste Management Corporation |

| Saskatchewan | Recyc-Québec |

| Yukon | Saskatchewan Waste Reduction Council |

- RDF Production

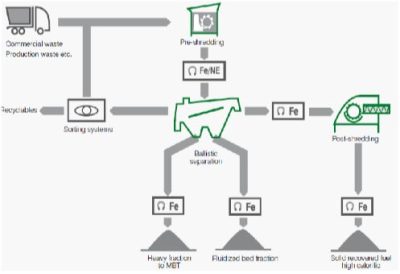

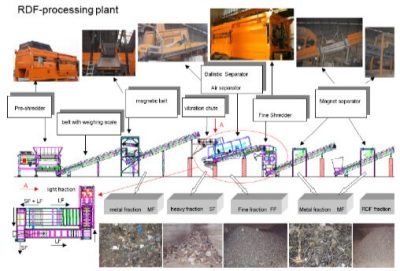

waste disposal methods have effect on required equipment to make standard RDF and also feasibility of RDF production. Input of RDF making plants would be No-recyclable and No-wet wastes to produce RDF economically with acceptable chemical parameters to be burnt in cement kilns. Standard of RDF chemical parameters for burning in cement kilns has shown in table I also Following schematic graphs show RDF producing plant stages and components

- RDF burring in cement kilns

In cement kilns, combustion takes place under very high flame temperatures and relatively long residence times. These conditions are favorable for the burning of refuse waste and also could generate corresponding heat.

Cement industries are worry about effect of burning RDF on the production(Clinker) but referring to so far experiences as well as performed and ongoing studies and experimental investigation the result of co-processing RDF in the combustion process is acceptable technically and environmentally.

Please see the references, at the bottom of the page, to find out acceptable specification of RDF for burning in a cement kiln

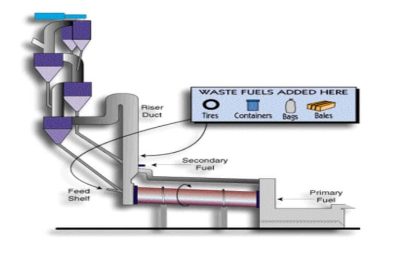

There are some points in Pyro-processing department of a cement production line through which Alternative Fuel could be used. The locations are shown in flowing schematic diagram:

It is notable that RDF with acceptable specification and suitable for burning in a cement pyro-processing system could be injected and burnt through the PH and the main fuel burner using different kind of technologies.

following factors are effective on selection of proper technology for burning RDF in a cement plant:

-

- Specifications of available the RDF

- The cement production line process condition

- Allowable and concerned substitution rate of RDF

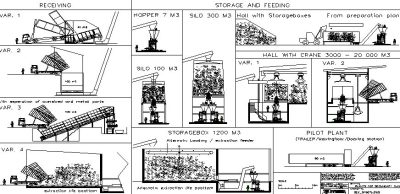

Selecting RDF Handling system in a cement plant is very important due to RDF specification and amount of the consumption in terms of receiving as well as storage and feeding.

Different kind of RDF handling systems comprising of receiving as well as storage and feeding are shown in following pictures.

So, among variety of technologies for utilizing RDF as AF in a cement plant developing the project correctly through preparing feasibility study including technical and commercial studies with an executive approach simultaneously for RDF burning is vital and necessary before starting each individual the project for a cement plant

- Utilizing RDF as AF in cement plants

In order to utilize RDF as AF in a cement plant 5 parties would be involved. There are 4 beneficiary parties which known as stockholder of the project as follows:

1- Local Waste Management Association (WMA) – as RDF producer

2- Local Cement Plant (CP)- as RDF consumer

3- RDF making technology provider

4- RDF handling and burning technology provider

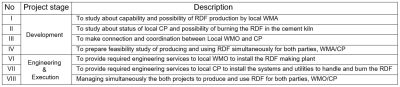

In Meantime it is essential to have 5th party to go through and perform following steps to develop and finally stablish the project:

NAMICO ENERGY ENTERPRISE Inc. standing by and accompany RDF producers (WMO’s) and RDF consumers (CP’s) to go through and perform aforementioned essential steps up to utilize RDF as Alternative Fuel in cement plants

Reference

Download PDF files